Never use hose unsupported

A wide range of composite hoses cover various applications. This could be to carry chemical vapor recovery and mineral oils and acids. Rugged, lightweight design and flexibility make the composite hoses easy to use. However if customers cannot use correctly, they will be damaged in the daily use. In order to give customers a better knowledge of composite hose installation therefore we offer composite hose guides to achieve the best results.

Never use hose unsupported

Always support hose near couplin

It's not correct to keep your composite hose from touching with sharp edges. If it is necessary you should use soft material supporting.

Hose cannot hang in the air

Support composite hose near coupling

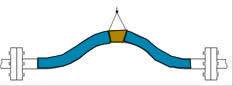

In the above picture we can see the composite hose is excessive sagging. And it’s the wrong operation.

To avoid excessive sagging of composite hoses, we should use a hanging support in the middle of the hoses to keep balance.

Avoid excessive sagging

Using support to avoid excessive sagging

In the above picture we can see the composite hose is excessive sagging. And it’s the wrong operation.

To avoid excessive sagging of composite hoses, we should use a hanging support in the middle of the hoses to keep balance.

Composite hose bends excessively

Using a pipe bend to avoid excessive bend

The composite hose should not excessive bend. We can use a pipe bend near the valve to avoid composite hose excessive bending.

Composite hose is abrasion coating damaged

Using a nylon sling belt when lifting hose

Customers can not lift the composite hose using only a rope because the action will damage the abrasion coating.

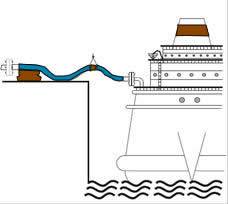

Composite hose sags between sides of the quay and the ship

Composite hose supported by using slings and other overhead supports